The clay which is prepared as above is then sent for the text operation of moulding.Following are two types of moulding:

i. Hand Moulding

ii. Machine Moulding

Hand moulding:

In hand moulding , the bricks are moulded by hand i.e.; manually. It is adopted where manpower is cheap and is readily available for the manufacturing process of bricks ona small scale.The moulds are rectangular boxes which are open at top and bottom.They may be of wood or steel.It should be beprepared from well-seasonedwood. The longer sides are kept slightly projecting to serve as handles. The strips of brass or steel are sometimes fixed on the edges of wooden moulds to make them more durable.It is prepared from the combination of steel plate and channel. It may even be prepared from steel angles and plates. Thethickness of steel mould is 6mm.They is used for manufacturing bricks on alarge scale. The steel moulds are more durable than wooden one and turn out bricks of uniform size.The bricks shrink during drying and burning .Hence the mouldsare therefore made larger than burnt bricks (8- 12%).

The bricks prepared by hand moulding are of two types: Ground mouldedand Tablemoulded

Ground mouldedbricks: The ground is first made level and fine sand is sprinkled over it.The mould is dipped in water and placed over the ground. The lump of tempered clay is taken and is dashed is the mould.The clay is pressed in the mould in such a way that it fills all the corners of mould.The surplus clay is removed by wooden strike or framed with wire. A strike is a piece of wood or metal with a sharp edge.It is to be dipped in water every time.The mould is then lifted up and raw brick ids left on the ground.The mould is dipped in water and it is placed just near the previous brick to prepare another brick.The process is repeated till the ground is covered with raw bricks.The lower faces of ground moulded bricks are rough

5 * Under revision

and it is not possible to place frog on such bricks.A frog is mark of depth about 10mm to 20mm which is placed on raw brick during moulding.It serves two purposes.

1.It indicates the trade name of the manufacturer

2.In brick work, the bricks are laid with frog uppermost. It thus affords a key for mortar when the next brick is placed over it.

The ground moulded bricks of better quality and with frogs on their surface are made by using a pair of pallet boards and a wooden block. A pallet is a piece of thin wood.The block is bigger than the mould and it has projection of about 6mm height on its surface.The dimensions of projection correspond to internal dimensions of mould.The design of impression or frog is made on this block.The wooden block is also known as the moulding block or stock board.

The mould is placed to fit in the projection of wooden block and clay is then dashed inside the mould.A pallet is placed on the top and the whole thing is then turn upside down.The mould is taken out and placed over the raw brick and it is conveyed to the drying sheds.The bricks are placed to stand on their longer sides in drying sheds and pallet boards are brought back for using them again.As the bricks are laid on edge, they occupyless space and they dry quicker and better.

Table Moulded Bricks:

i) The process of moulding of bricks is just similar as above.But in this case, the mould stands near a table size 2m x 1m. The bricks are moulded on the table and send for further process of drying.

ii) However the efficiency of the moulder gradually decreases because of standing at some place for a longer duration.The cost of brick is also increases when table moulding is adopted.

Machine Moulding:

This type of moulding is carried out by two processes:

i) Plastic clay machine

ii) Dry clay machine

Plastic Clay Moulding

i) Such machine consists of a rectangular opening having length and width is equal to an ordinary bricks. The pugged clay is placed in the machine and it comes out through the rectangular opening.

ii) These are cut into strips by the wire fixed at the frame. The arrangement is made in such a way that the strips thickness is equal to that of the bricks are obtained. So it is also called as WIRE CUT BRICKS.

6 * Under revision

Dry Clay Machinemoulding:

In these machines, the strong clay is finally converted in to powered form.A small quantity of water is then added to form a stiff plastic paste.

ii) Such paste is placed in mould and pressed by machine to form dry and well-shaped bricks. They do not require the process of drying.

Drying

The damp bricks, if brunt,are likely to be cracked and distorted.Hence the moulded bricks are dried before they are taken for the next operation of burning. For the drying the bricks are laid longitudinally in the stacks of width equal to two bricks,A stack consists of ten or eight tiers.The bricks are laid along and across the stock in alternate layers. All the bricks are placed on edges. The bricks are allowed to dry until the bricks are become leather hard of moisture content about 2%.

Burning

Bricks are burned at high temperature to gain the strength, durability, density and red color appearance.All the water is removed at the temperature of 650 degrees but they are burnt at an temperature of about 1100 degrees because the fusing of sand and lime takes place at this temperature and chemical bonding takes between these materials after the temperature is cooled down resulting in the hard and dense mass.

Bricks are not burnt above this temperature because it will result in the melting of the bricks and will result in a distorted shape and a very hard mass when cooled which will not be workable while brickwork. Bricks can be burnt using the following methods:

(a) Clamp Burning (b) Kiln Burning

Clamp Burning:

Clamp is a temporary structure generally constructed over the ground with a height of about 4 to 6 m. It is employed when the demand of the bricks is lower scale and when it is not a monsoon season. This is generally trapezoidal in plan whose shorter edge among the parallel sides is below the ground and then the surface raising constantly at about 15 degrees to reach the other parallel edge over the ground.A vertical brick and mud wall is constructed at the lower edge to support the stack of the brick. First layer of fuel is laid as the bottom most layer with the coal, wood and other locally available material like cow dung and husk.Another layer of about 4 to 5 rows of bricks is laid and then again a fuel layer is laid over it. The thickness of the fuel layer goes on with the height of the clamp.

7 * Under revision

After these alternate layers of the bricks and fuel the top surface is covered with the mud so as to preserve the heat.Fire is ignited at the bottom, once fire is started it is kept under fire by itself for one or two months and same time period is needed for the cooling of the bricks.

Disadvantages of Clamp burning:

1. Bricks at the bottom are over-burnt while at the top are under-burnt.

2. Bricks loose their shape, and reason may be their descending downward once the fuel

layer is burnt.

3. This method cannotemploy for the manufacturing of large number of bricks and it is costly in terms of fuel because large amount of heat is wasted.

4. It cannot be employed in monsoon season.

Kiln Burning:

Kiln is a large oven used for the burning of bricks. Generally coal and other locally available materials like wood, cow dung etc can be used as fuel. They are of two types:

• Intermittent Kilns. • Continuous Kilns.

Fig of a typical kiln

8 * Under revision

Intermittent Kilns: these are also the periodic kind of kilns, because in such kilns only one process can take place at one time. Various major processes which takes place in the kilns are:Loading, unloading, Cooling, and Burning of bricks.

There are two kind of intermittent kilns:

(i) Up-draught Intermittent Kilns

(ii) Down draught Intermittent Kilns

Down draught kilns are more efficient because the heat is utilized more by moving the hot gases in the larger area of the kiln. In up draught kilns the hot gases are released after they rise up to chimney entrance.

Continuous Kilns:

These kilns are called continuous because all the processes of loading, unloading, cooling, heating, pre-heating take place simultaneously. They are used when the bricks are demanded in larger scale and in short time. Bricks burning are completed in one day, so it is a fast method of burning.There are two well-known continuous kilns:

Bull's Trench Kiln:Bull's trench kiln consists of a rectangular, circular or oval plan shape. They are constructed below the ground level by excavating a trench of the required width for the given capacity of brick manufacturing.This Trench is divided generally in 12 chambers so that 2 numbers of cycles of brick burning can take place at the same time for the larger production of the bricks. Or it may happen that one cycle is carried out at one time in all the 12 chambers by using a single process in the 2-3 chambers at the same time.The structure is under-ground so the heat is conserved to a large extent so it is more efficient. Once fire is started it constantly travels from one chamber to the other chamber, while other operations like loading, unloading, cooling, burning and preheating taking place simultaneously.

Such kilns are generally constructed to have a manufacturing capacity of about 20,000 bricks per day. The drawback of this kiln is that there is not a permanent roof, so it is not easy to manufacture the bricks in the monsoon seasons.

Hoffman's Kiln:The main difference between the Bull's trench kiln and the Hoffman kilns are:

1. Hoffman's kiln is an over the ground structure while Bull's Trench Kiln is an underground structure.

2.Hoffman's kiln have a permanent roof while Bull's trench Kiln do not have so it former can be used in 12 months a year to manufacture bricks but later is stopped in the monsoon season.

Hoffman's kiln is generally circular in plan, and is constructed over the ground. The whole structure is divided into the 12 chambers and the entire processes takes place simultaneously like in Bull's trench Kiln.

9 * Under revision

Classification of Bricks as per common practice:

Bricks, which are used in construction works, are burnt bricks. They are classified into four categories on the basis of its manufacturing and preparation, as given below.

1. First class bricks

2. Second class bricks 3. Third class bricks 4. Fourth class bricks

First Class Bricks:

These bricks are table moulded and of standard shape and they are burnt in kilns. The surface and edges of the bricks are sharp, square, smooth and straight. They comply with all the qualities of good bricks. These bricks are used for superior work of permanent nature.

Second Class Bricks:

These bricks are ground moulded and they are burnt in kilns. The surface of these bricks is somewhat rough and shape is also slightly irregular. These bricks may have hair cracks and their edges may not be sharp and uniform. These bricks are commonly used at places where brick work is to be provided with a coat of plaster.

Third Class Bricks:

These bricks are ground moulded and they are burnt in clamps. These bricks are not hard and they have rough surfaces with irregular and distorted edges. These bricks give dull sound when struck together. They are used for unimportant and temporary structures and at places where rainfall is not heavy.

Fourth Class Bricks:

These are over burnt bricks with irregular shape and dark colour. These bricks are used as aggregate for concrete in foundations, floors, roads etc, because of the fact that the over burnt bricks have a compact structure and hence they are sometimes found to be stronger than even the first class bricks.

Classification of Bricks as per constituent materials

There are various types of bricks used in masonry.

• Common Burnt Clay Bricks

• Sand Lime Bricks (Calcium Silicate Bricks)

• Engineering Bricks

• Concrete Bricks

• Fly ash Clay Bricks

10 * Under revision

Common Burnt Clay Bricks

Common burnt clay bricks are formed by pressing in moulds. Then these bricks are dried and fired in a kiln. Common burnt clay bricks are used in general work with no special attractive appearances. When these bricks are used in walls, they require plastering or rendering.

Sand Lime Bricks

Sand lime bricks are made by mixing sand, fly ash and lime followed by a chemical process during wet mixing. The mix is then moulded under pressure forming the brick. These bricks can offer advantages over clay bricks such as: their colour appearance is grey instead of the regular reddish colour.Their shape is uniform and presents a smoother finish that doesn’t require plastering.These bricks offer excellent strength as a load-bearing member.

Engineering Bricks

Engineering bricks are bricks manufactured at extremely high temperatures, forming a dense

and strong brick, allowing the brick to limit strength and water absorption.Engineering bricks offer excellent load bearing capacity damp-proof characteristicsand chemical resisting properties.

Concrete Bricks

Concrete bricks are made from solid concrete. Concrete bricks are usually placed in facades, fences, and provide an excellent aesthetic presence. These bricks can be manufactured to provide different colours as pigmented during its production.

Fly Ash Clay Bricks

Fly ash clay bricks are manufactured with clay and fly ash, at about 1,000 degrees C. Some studies have shown that these bricks tend to fail poor produce pop-outs, when bricks come into contact with moisture and water, causing the bricks to expand.

Tests on Bricks

To know the quality of bricks following 7 tests can be performed. In these tests some are

performed in laboratory and the rest are on field.

11 * Under revision

• Compressive strength test

• Water Absorption test

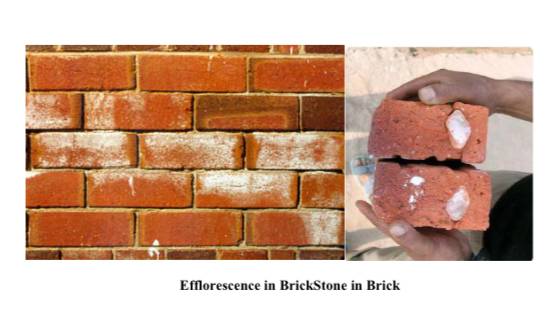

• Efflorescence test

• Hardness test

• Size, Shape and Colour test

• Soundness test

• Structure test

Compressive strength test: This test is done to know the compressive strength of brick. It is also called crushing strength of brick. Generally 5 specimens of bricks are taken to laboratory for testing and tested one by one. In this test a brick specimen is put on crushing machine and applied pressure till it breaks. The ultimate pressure at which brick is crushed is taken into account. All five brick specimens are tested one by one and average result is taken as brick’s compressive/crushing strength.

Water Absorption test: In this test bricks are weighed in dry condition and let them immersed in fresh water for 24 hours. After 24 hours of immersion those are taken out from water and wipe out with cloth. Then brick is weighed in wet condition. The difference between weights is the water absorbed by brick. The percentage of water absorption is then calculated.The less water absorbed by brick the greater its quality. Good quality brickdoesn’t absorb more than 20% water of its own weight.

Efflorescence test: The presence of alkalies in bricks is harmful and they form a grey or white layer on brick surface by absorbing moisture. To find out the presence of alkalis in bricks this test is performed. In this test a brick is immersed in fresh water for 24 hours and then it’s taken out from water and allowed to dry in shade.If the whitish layer is not visible on surface it proofs that absence of alkalis in brick. If the whitish layer visible about 10% of brick surface then the presence of alkalis is in acceptable range. If that is about 50% of surface then it is moderate. If the alkalies’ presence is over 50% then the brick is severely affected by alkalies.

Hardness test: In this test a scratch is made on brick surface with a hard thing. If that doesn’t left any impression on brick then that is good quality brick.

Size, shape and colour test: In this test randomly collected 20 bricks are staked along lengthwise, width wise and height wise and then those are measured to know the variation of sizes as per standard. Bricks are closely viewed to check if its edges are sharp and straight

12 * Under revision

and uniform in shape. A good quality brick should have bright and uniform colour throughout.

Soundness test: In this test two bricks are held by both hands and struck with one another. If the bricks give clear metallic ringing sound and don’t break then those are good quality bricks.

Structure test: In this test a brick is broken or a broken brick is collected and closely observed. If there are any flows, cracks or holes present on that broken face then that isn’t good quality brick.

No comments yet

Be the first to share your thoughts!