10. DOORS AND WINDOWS

TYPES OF WINDOWS

Depending upon the manner of fixing, materials used for construction, nature of the operational movements of shutters , etc., the common varieties of windows used in the building can be grouped as follows:

1. Casement windows

2. Sliding windows

3. Metal windows

4. Corner windows

5. Gable windows bay windows

6. Lantern or lantern lights

7. Skylights

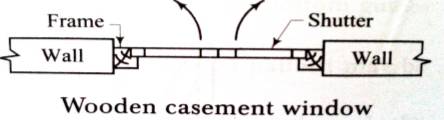

CASEMENT WINDOWS:

These are the windows, the shutters of which open like doors. The construction of a casement window is similar to the door construction.

SLIDING WINDOWS:

These windows are similar to the sliding doors and the shutters moves on the roller bearings, either horizontally or vertically. Such windows are provided in trains, buses, bank counter, shops etc.

76 * Under revision

Painting of various surfaces:

A. New plastered surface:

The procedures for paining a new plastered surface are:

1. Surface preparation: Paint cannot take care of construction defects. Before applying the paint, it is ensured that the surface is free from dust, dirt, loose matter, grease etc. and is rubbed with an emery paper, to provide a mechanical key between surface and paint for satisfactory adhesion.

2. Sequence of Painting: The primer (first coat) is applied with brush or spray on the prepared surface. It should be thinned with water or thinner in the recommended manner and proportion before application. After drying it is rubbed with emery paper. Dents and cracks, if any, are filled with putty using a knife applicator. Putty should not be applied thick. If the required thickness is large, it should be applied in two coats. After the putty has dried, the whole surface is rubbed down well in order to smoothen the putty andprovide a mechanical key to the finished coats. Two or three finish coats are applied. Each coat is allowed to dry before the application of next coat.

B. Oldplasteredsurface

The procedure depends on the state of the existing coating. If any of the defects discussed below is very much pronounced it is completely removed and the surface is painted as a new surface.

C. Painting of new woodwork

Painting of woodwork should be done with great care. Normally 3–4 coats are sufficient for wood work.

• Surface preparation: The wood should be well seasoned, dried, cleaned and the surface made smooth with an emery paper. Nails, if any, should be driven down the surface by at least 3 mm.

• Knotting: Knots in the wood create lot of problems. These excrete resin which causes defects such as cracking, peeling and brown discolouration. Knotting is done so that resin cannot exude from the knots. Any of the following methods may be used suitably.

91 * Under revision

Ordinary knotting: This is also known as size knotting. The knot is treated with a coat of hot red lead ground with a strong glue size in water. Then a coat of red lead ground in boiled linseed oil is applied.

Lime knotting: The knot is covered with hot lime for 24 hours after which it is scrapped off. Thereafter, the process described in ordinary knotting is followed.

Patent knotting: Two coats of varnish or shelac are applied.

• Priming coat: The main function of priming coat or primer is to form the base for subsequent ones. After knotting priming coat is applied over the entire surface to fill all the pores. A second priming coat is applied after first has dried. In general the ingredients are same as those of the subsequent coats but with a difference in proportion.

• Stopping: After the priming coat putty is applied to fill the pores of the surface. Then it is rubbed smooth. Colouring pigment is also added to it to match the shade of the finished coat. On drying, the selected paint is applied with brushes to bring smoothness and uniformity in colour. After painting the surface in one direction, the brush is worked in the perpendicular direction to eliminate brush marks. This is known as crossing. All the successive coats are applied after drying and slight rubbing of previous coats for proper bond.

D. Painting of old woodwork:

The old paint is removed with a sharp glass piece, sand paper, paint remover or with a blow lamp. Any smoky or greasy substance should be washed with lime and subsequently rubbed with pumice stone. The surface is then washed with soap and water and dried completely. Then two coats of paints are applied in a way similar to that described in painting new surfaces.

E. Paintingmetalsurfaces:

• New ironwork: The surface should be free from scales, rust and grease. Scales and rust are cleaned by hard wire brush. Grease is removed by using petroleum or by hot alkaline solution of Na2CO3 or NaOH, benzene, and lime water. A priming coat of red lead with barytes and raw linseed oil is then applied over the prepared surface. After drying of the priming coat, one or more undercoats with desired paint are applied. The second coat is given only after the first coat has dried. The finishing coat is applied carefully to produce a smooth fine surface.

92 * Under revision

• Old ironwork: The surface is prepared by scraping properly all the scales and rust with emery paper. The greasy substances are removed with lime water. The old paint may be burned with a blow lamp or by suitable solvents. After this the surface is brushed with hot linseed oil and painted as for new iron work.

• Structural steel: The major problem to overcome in painting iron and steel is corrosion due to electrolysis caused by the presence of air and moisture. Red lead is considered to be the best priming coat; it produces a tough elastic film, impervious to air and moisture. Pure linseed oil priming coat is detrimental in that it stimulates corrosion. The linseed oil film is rendered more impervious by the use of spar varnish. Graphite paint used for black colour, is very durable and is not affected by sulphur films, ammonia or chlorine gases. Silica-graphite paints are best; they do not crack and blister in course of time. Aluminium paint is also gaining popularity because of its shining and contrast properties and heat and chemical resistance. Bituminous paints may be very well adopted to paint inside of pipes, iron under waters, piles, ships and boats; they are unsatisfactory when exposed to sunlight. Lead or zinc paint should never be applied directly over the iron surface as it encourages galvanic action destroying the paint.

F. Painting of floor surfaces: The enamels are used for painting of floor surfaces. The selected enamel should be strong enough to resist abrasion, moisture, and alkali actions. It should be of shinning nature and quick drying type.

G. Painting of concrete surfaces: The cement paint is used to paint concrete surfaces. The paint is available in a powder form and it is dissolved in water to workable consistency. The paint thus prepared should be consumed with in 2 to 3 hours. The two coats are applied at an interval to provide curing of painted surface.

93 * Under revision

No comments yet

Be the first to share your thoughts!