A double stage, nanostructured high-entropy compound that has been 3D printed by specialists from the University of Massachusetts Amherst and the Georgia Institute of Technology is more grounded and more malleable than other forefront additively produced materials. This revelation could prompt better execution parts for use in aviation, medication, energy, and transportation.

The exploration was distributed web-based by the diary Nature and was going by Wen Chen, an associate teacher of mechanical and modern designing at UMass, and Ting Zhu, a teacher of mechanical designing at Georgia Tech.High entropy compounds (HEAs), as they are called, have acquired prominence as another worldview in materials science throughout the course of recent years. They consider the production of an almost boundless number of various composite plans since they remember at least five components for almost equivalent sums. Metal, carbon steel, hardened steel, and bronze are instances of conventional compounds that blend a main component in with at least one minor components.

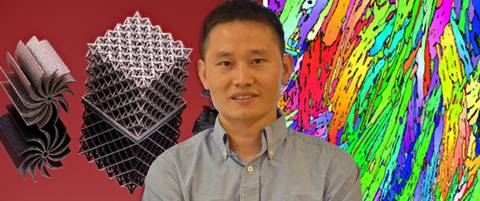

A cross-sectional electron backscatter diffraction opposite post figure map showing a haphazardly situated nanolamella microstructure and pictures of 3D printed high-entropy compound parts are shown before Wen Chen, an associate teacher of mechanical and modern designing at UMass Amherst (right).Additive producing, likewise called 3D printing, has as of late arisen as a strong way to deal with material turn of events. The laser-based 3D printing can create huge temperature inclinations and high cooling rates that are not promptly available by regular courses. Nonetheless, "the capability of outfitting the consolidated advantages of added substance fabricating and HEAs for accomplishing novel properties remains to a great extent neglected," says Zhu.

A HEA was joined with a state of the art 3D printing strategy called laser powder bed combination by Chen and his group at the Multiscale Materials and Manufacturing Laboratory to make novel materials with unfathomable characteristics. When contrasted with customary metallurgy, the methodology makes materials liquefy and cement significantly more rapidly, which results in "a totally different microstructure that is a long way from-balance" on the parts delivered, claims Chen.

The new material looks like a net when seen at the nanoscale

This microstructure, which looks like a net, is made out of exchanging layers of face-focused cubic (FCC) and body-focused cubic (BCC) nanolamellar structures that are encased in little, haphazardly situated eutectic settlements. The two stages can agreeably distort thanks to the various leveled nanostructured HEA.This surprising microstructure's nuclear modification leads to ultrahigh strength as well as improved malleability, which is remarkable, on the grounds that generally solid materials will quite often be weak," Chen made sense of. Contrasted with customary metal projecting, "we got practically triple the strength and didn't lose malleability, yet really expanded it all the while," he says. "For some applications, a blend of solidarity and pliability is critical. Our discoveries are unique and invigorating for materials science and designing the same," he added.

"The capacity to create solid and bendable HEAs implies that these 3D pieces of literature are more powerful in opposing applied distortion, which is significant for lightweight underlying model for upgraded mechanical productivity and energy saving," says Jie Ren, Chen's Ph.D. understudy and first creator of the paper. The computational demonstrating for the review was facilitated by Zhu's group at Georgia Tech. To fathom the mechanical jobs played by both the FCC and BCC nanolamellae and how they participate to give the material more strength and flexibility, he built double stage precious stone pliancy PC models.

"Our reproduction results show the shockingly high strength yet high solidifying reactions in the BCC nanolamellae, which are essential for accomplishing the exceptional strength-malleability collaboration of our composite. This robotic comprehension gives a significant premise to directing the future advancement of 3D printed HEAs with outstanding mechanical properties," Zhu says.

Furthermore, 3D printing gives major areas of strength for a to delivering leaves behind multifaceted calculations. Future direct assembling of end-use parts for biomedical and aviation applications will have a lot of choices because of the blend of 3D printing innovation and the gigantic composite plan space of HEAs.

You can see the whole review for yourself in the diary Nature.Study dynamic:

"Added substance fabricating produces net-molded parts layer by layer for designing applications1,2,3,4,5,6,7. The added substance production of metal compounds by laser powder bed combination (L-PBF) includes enormous temperature slopes and quick cooling2,6, which empowers microstructural refinement at the nanoscale to accomplish high strength. Be that as it may, high-strength nanostructured compounds delivered by laser added substance fabricating frequently have restricted ductility3. Here we utilize L-PBF to print double stage nanolamellar high-entropy compounds (HEAs) of AlCoCrFeNi2.1 that display a blend of a high return strength of around 1.3 gigapascals and an enormous uniform prolongation of around 14%, which outperforms those of other cutting edge additively produced metal composites. The high return strength comes from areas of strength for the impacts of the double stage structures that comprise of rotating face-focused cubic and body-focused cubic nanolamellae; the body-focused cubic nanolamellae show higher qualities and higher solidifying rates than the face-focused cubic nanolamellae. The enormous tractable malleability emerges attributable to the high work-solidifying ability of the as-printed progressive microstructures as double stage nanolamellae implanted in microscale eutectic provinces, which have almost irregular directions to advance isotropic mechanical properties. The unthinking experiences into the misshapening conduct of additively produced HEAs have expansive ramifications for the improvement of progressive, double and multi-stage, nanostructured composites with excellent mechanical properties."

No comments yet

Be the first to share your thoughts!